Universal Estimating

Woodman Estimating uses materials and labour data together with overhead and profit rates to build up product costs and calculate selling prices. These are stored as estimates which can be recalled and reused as required. A priced, illustrated quotation with customer sign-off and personalised accompanying letter is produced.

One-off products can be built up by entering the material codes, quantities, sizes and labour times in accordance with the specification. Data can be entered in whatever form the estimator finds most convenient.

Regular products can be specified using parametrics, such as formulae and variables so that items can be copied and modified by changing dimensions and materials to reproduce an alternative specification. Numerous designs can be created in this way and stored where they can be easily located and copied to new estimates and modified as required.

Reports can be produced for each product showing the detailed material cost, labour time and overhead build-up. Reports layouts can be personalised to individual companies.

Summary reports for the whole estimate showing the total materials and labour cost plus labour hours and gross profit can be produced together with a list of priced items for attachment to a quotation.

Materials data for timber, board and hardware items is stored on the main materials library file which can be accessed when building up product specifications. Materials unique to specific estimates can be kept on a special materials file associated with each estimate.

Labour time allowances are entirely flexible in their application to the system. Predetermined time allowances can be used or modified to suit special circumstances. Alternatively the user can simply key in required time allowances at the data entry stage. Machining times can include a fixed set-up allowance to be divided by a batch factor plus processing times to reflect the cost of different batch sizes.

Product Configurator

The Woodman Product Configurator is designed specifically for manufacturers of “Make To Order” and “Configure To Order” products. It is particularly suitable for products with multiple options, colours, accessories, materials etc. The Woodman Product Configurator works with Woodman Estimating and Woodman Production Modules.

The Woodman database stores detailed information for parts, materials and labour operations for all production jobs, thus enabling integration into other manufacturing and scheduling software systems and bespoke report generators.

Estimates and production jobs can be quickly processed by designating the standard options and variables required then specifying each product design reference with a quantity and size. Any products with non-standard options or variables can be modified as required.

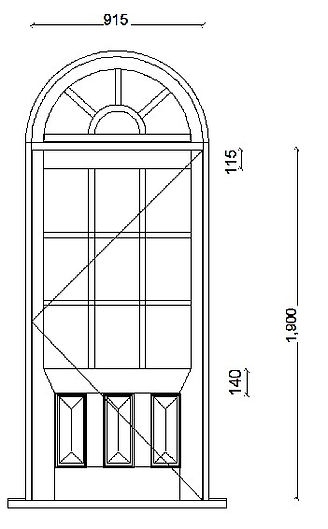

The Woodman Product Configurator allows for quick and accurate data entry of complex products with dimensions, options and choices. Operators are able to configure to order parametric products such as windows, doors, glass etc. Powerful, rules based product design configurations eliminate product specification errors.

Key Benefits

-

Less skill requirement to specify complex products.

-

Protects against specifying ‘unmakeable’ products.

-

‘On the fly’ parametric bills of materials and labour routings.Machining operations can be specified so that machine routing and labour time allowances can be built-up to provide detailed machining information for components. The production planning reports provide machine loading and routing information to assist planning and control of component manufacture.

The Universal component database is directly accessible within the Estimates & Production modules, thus enabling operators to quickly build up bespoke products from a predetermined set of parametric components.